MICROSCOPE-ANTIQUES.COM © 2013-21.

CONTAINERS FOR DISPENSING IMMERSION OIL:

INTRODUCTION:

With the light microscope, the highest resolution at high magnification requires the use of immersion oil. In use, a small amount is placed between the front lens of the objective and the surface of the slide; additional oil is often used between the condenser and the bottom of the slide to obtain maximal resolution. Although the use of oil in this way was first developed about 1870 by Tolles using liquified Canada Balsam, (refractive index 1.52 to 1.55), this material was difficult to use for this purpose, and the technique was not widely accepted for years afterwards. Zeiss first made oil immersion lenses about 1877. By the 1880's, oil immersion objectives had become widely available, especially from Germany. The first practical oil used was Cedar(wood)oil(in German Cedern oel

). This oil has a refractive index very close to glass. This was the standard oil for many years. Cedar oil has drawbacks however. First, it tends to dry out, forming a gummy residue. In some cases if left on the front element of the objective for too long, it can penetrate the lens mount and cause the optical elements to become decemented or permanently cloudy. It also gives off a strong odor and is yellow in color and gets darker with age. It was not until 1940. that synthetic non-drying oils were developed to replace Cedar oil. Cargille, the founder of a company still in existance today, was the first to produce synthetic non-drying immersion oil. It was not until about 1970 that synthetic immersion oils were free of PCB's, again Cargille being the first to produce these safer oils. Using oil requires a container to keep it stored, preferably air tight, and some small instrument to apply the oil; only a small drop is needed at a time. Another requirement is to have a cleaner, (which previously was a solvent*), to remove remnants of the oil from slides and lenses after the microscopy was completed. Over the years several designs of containers to hold and/or dispense immersion oil were developed. Until commercial non-drying oils became available, most of the major microscope manufacturers supplied immersion oil with their objectives, often specifically stating that only their own oil should be used.

At first, bottles of immersion oil (cedar oil or sometimes sandalwood oil) were simply plain ones, stoppered with cork or glass. Then various more convenient forms were developed. At the same time, ordinary glass bottles of immersion oil were often sold without any special applicator. The simplest addition would be an applicator within the bottle. This could be a wire with a loop on the end, a glass rod, a small brush, or a rod made of another material such as bone or hard rubber.

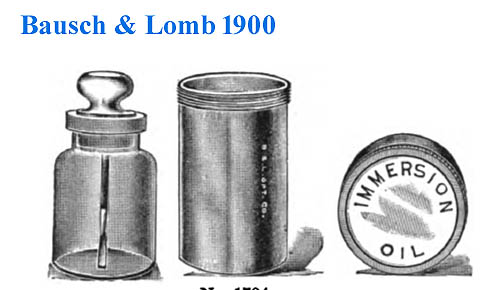

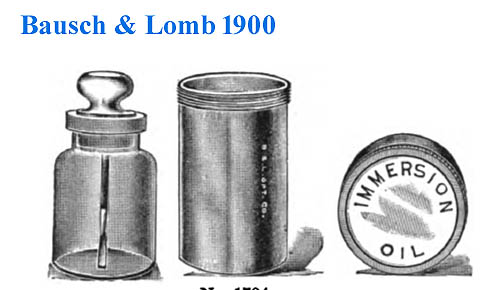

The first purpose made type of immersion oil bottle was simply a glass bottle with an applicator attached to the ground glass stopper. The applicator in this example by Bausch & Lomb is a camel-hair brush. Although the illustration shows a catalog entry from 1900, it was certainly available for years before that. The example shown here was designed to fit in a canister the same size as those for objectives, so it could store in the same fittings in the case as the objectives would. The lid served to hold the stopper firmly in place so oil would not leak out during traveling. Furthermore, the opening was wide enough to make it easier not to smear the oil on the sides of the opening when the stopper was withdrawn. This was important because cedar oil tends to dry out, gum up and might cause the stopper to become stuck.

The first purpose made type of immersion oil bottle was simply a glass bottle with an applicator attached to the ground glass stopper. The applicator in this example by Bausch & Lomb is a camel-hair brush. Although the illustration shows a catalog entry from 1900, it was certainly available for years before that. The example shown here was designed to fit in a canister the same size as those for objectives, so it could store in the same fittings in the case as the objectives would. The lid served to hold the stopper firmly in place so oil would not leak out during traveling. Furthermore, the opening was wide enough to make it easier not to smear the oil on the sides of the opening when the stopper was withdrawn. This was important because cedar oil tends to dry out, gum up and might cause the stopper to become stuck.

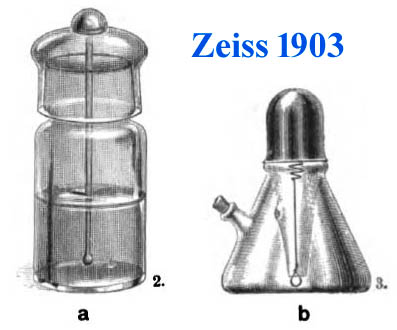

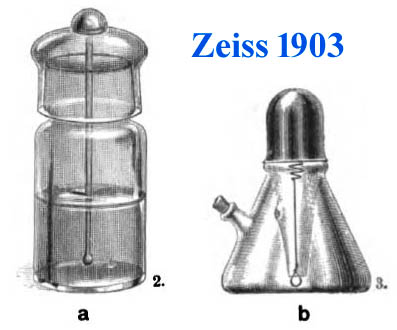

This is an example of a zeiss bottle with a glass rod integrated into the lid. Although this catalog entry is from 1903, it was certainly available for years prior to that as well.

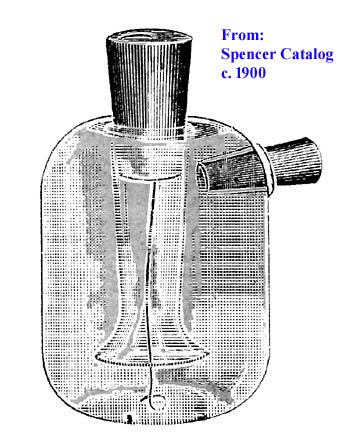

This is an example of a simple wide-based bottle with a loose rod and a ground glass cap which has been available for a great many years and in fact is still sold today. It was also used for keeping mounting media. In the 1900 Spencer catalog it was referred to as Balsam Bottle

.

Today this type of bottle is commonly used for immersion oil in places with high volumes of slides to review (like hospitals labs).

The idea of making a litle bottle that fit inside an objective canister was popular among many makers. This one by Leitz is but one other example. There is no applicator rod in this one but it is possible that it had one of glass and it had been accidentally or purposely broken off (some users did not like the relativly large drop of oil that glass rods dispensed).

Bausch & Lomb eventually came up with a bottle made entirely of metal, again in the size, and of the style, of an objective canister. This nickel-plated example has a pointed bone, horn, or hard rubber applicator attached to to metal stopper. Again tightening the lid held the stopper tightly in place preventing leakage. The Leitz catalog of 1907 mentions an oil immersion applicator bottle with

Bausch & Lomb eventually came up with a bottle made entirely of metal, again in the size, and of the style, of an objective canister. This nickel-plated example has a pointed bone, horn, or hard rubber applicator attached to to metal stopper. Again tightening the lid held the stopper tightly in place preventing leakage. The Leitz catalog of 1907 mentions an oil immersion applicator bottle with horn applicator

but does not illustrate it.

This oil bottle from Germany is another example of a bottle of oil fitting in an objective-type container. This one has a spring on the bottom so that the bottle pops out when the top of the can is unscrewed (image courtesy of James Solliday).

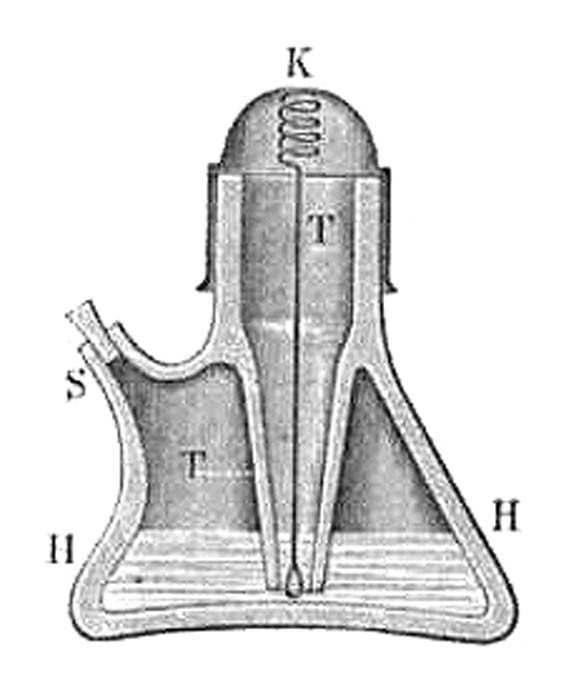

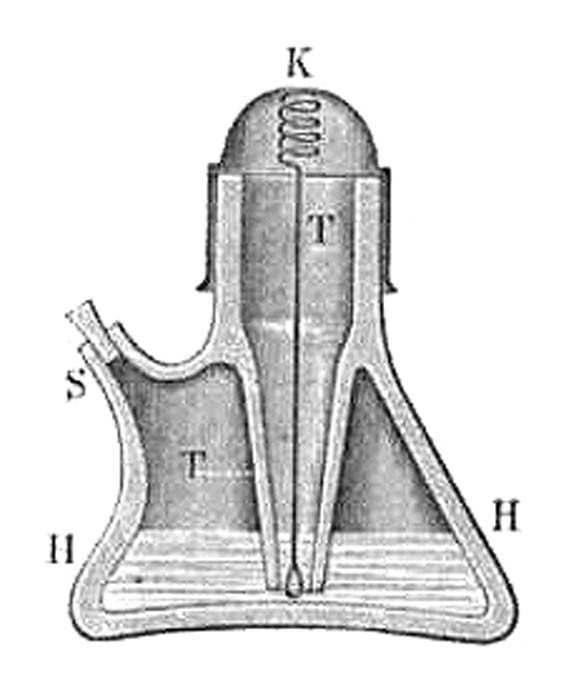

About 1897 Dr L Mach, of Zeiss in Germany, had devised a different kind of immersion oil receptacle, shown in cross section to the left. The overall conical shape was that of an Ehrlenmeyer flask. This was a single bottle with a inner glass cone through which a wire loop fit. There was a side port to fill the bottle and it was meant only to hold the oil such that a controlled amount could be removed and applied. The wide bottom prevented spillage. Note that the simpler cylinder-shaped type with glass rod applicator continued to be offered at the same time(right). For more details about this original form of Mach oil bottle, see here.

About 1897 Dr L Mach, of Zeiss in Germany, had devised a different kind of immersion oil receptacle, shown in cross section to the left. The overall conical shape was that of an Ehrlenmeyer flask. This was a single bottle with a inner glass cone through which a wire loop fit. There was a side port to fill the bottle and it was meant only to hold the oil such that a controlled amount could be removed and applied. The wide bottom prevented spillage. Note that the simpler cylinder-shaped type with glass rod applicator continued to be offered at the same time(right). For more details about this original form of Mach oil bottle, see here.

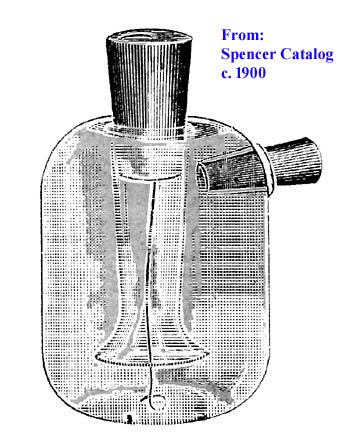

In a catalog from about 1900, Spencer offered Spencer Lens Co.'s special bottle and dropper for immersion oil, unspillable.

This bottle had features of the Mach design, including the inner cylinder and the wire eyelet. It came in two sizes.

About 1911, Bausch & Lomb came out with a bottle which had features similar to the Mach bottle, but smaller so that it was the size of an objective canister and could still fit into the furniture holes for objectives in the microscope cases. Like Mach's version, it had a wire eyelet on the end just protruding below a central funnel.

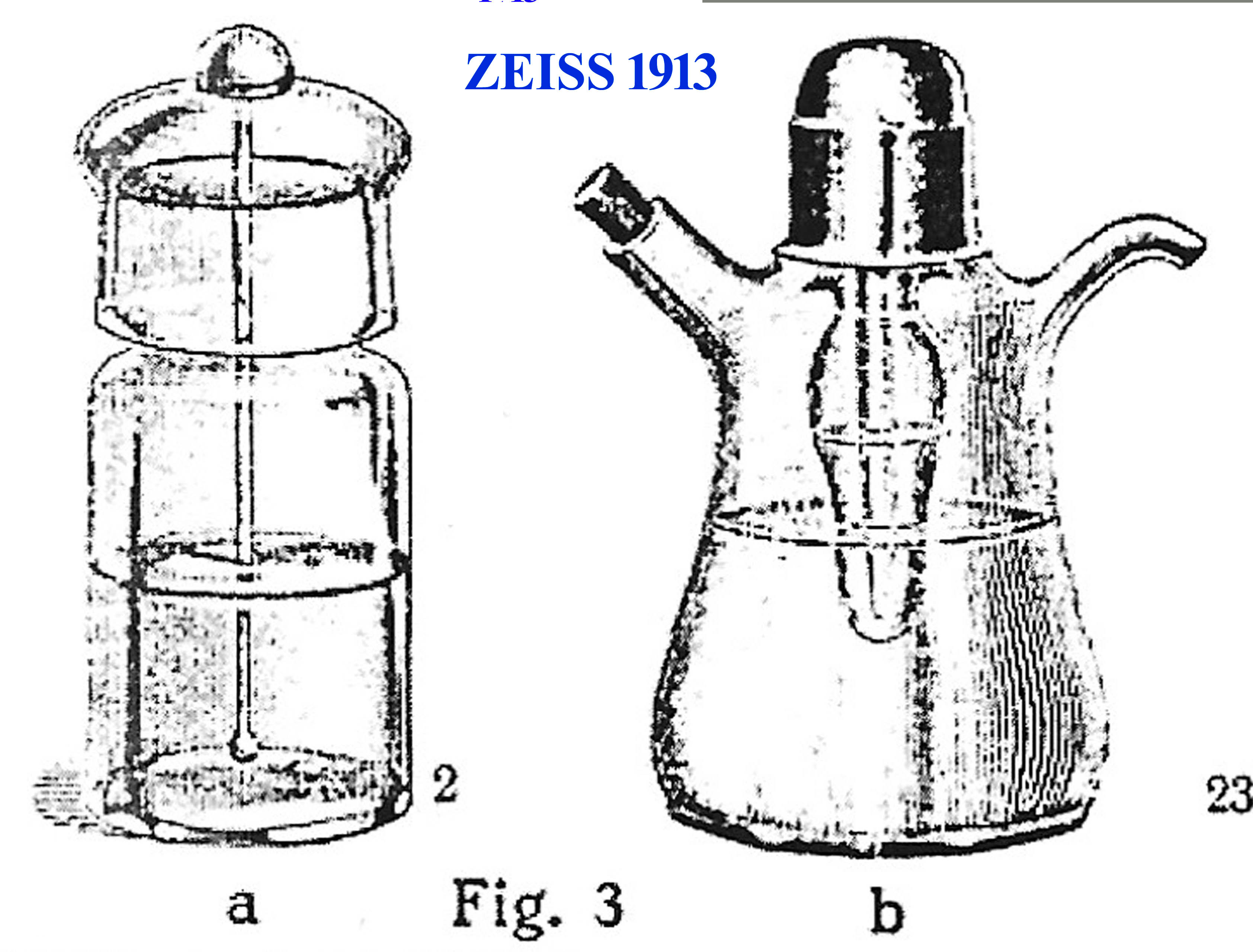

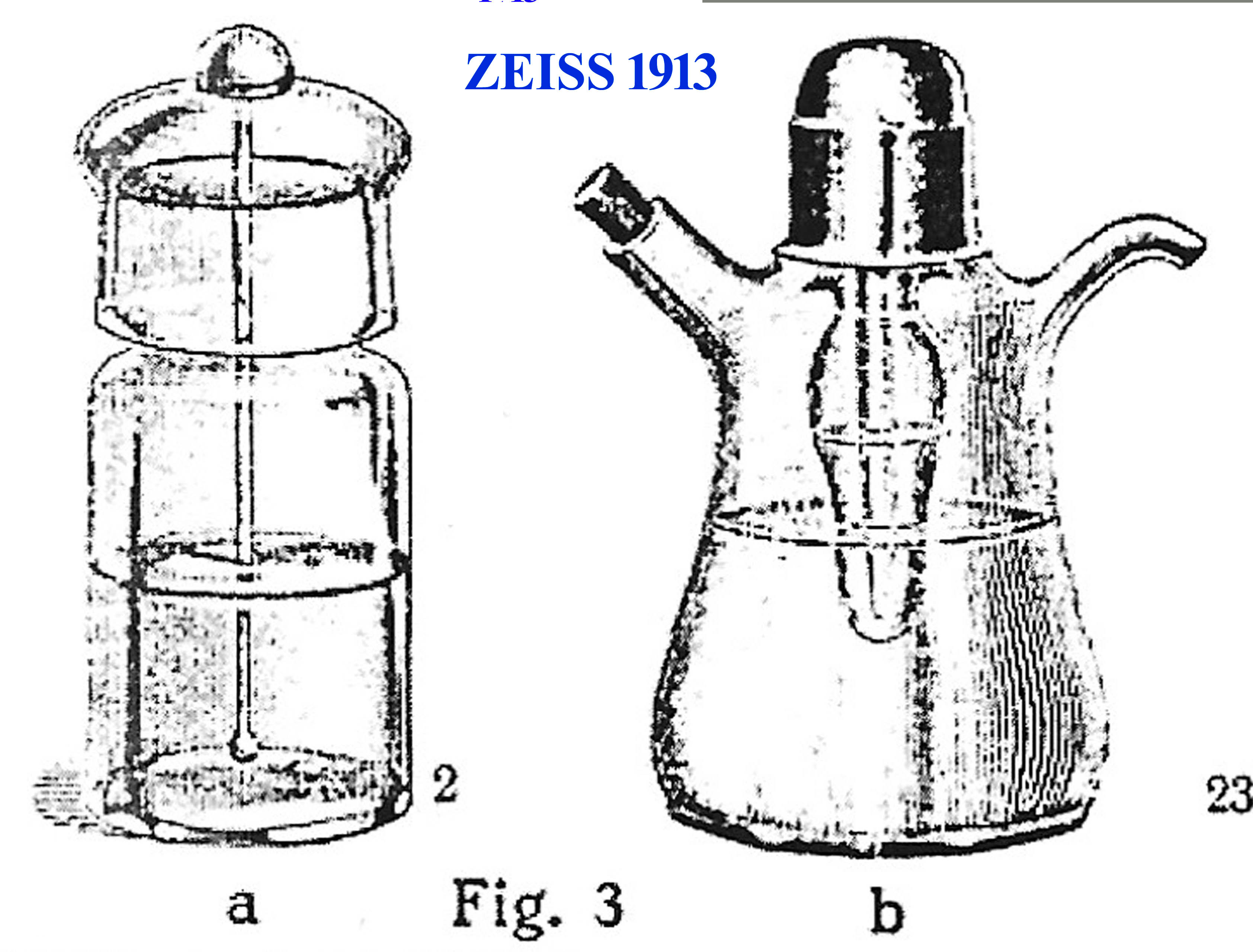

By 1913 Zeiss started to change the design of this bottle substantially, as shown in b, in the figure to the left. The inner portion was now closed at its bottom, and was the only part to hold the supply of oil. A glass rod which tapered at its bottom was now the applicator. The remaining outer portion of the flask was now reserved for solvent*. This model had a spout to pour out some solvent. This type of bottle was soon abandoned for the final iteration of this bottle, shown in the next paragraph. The simple cylinder-shaped model (a) was still offered during this period of time.

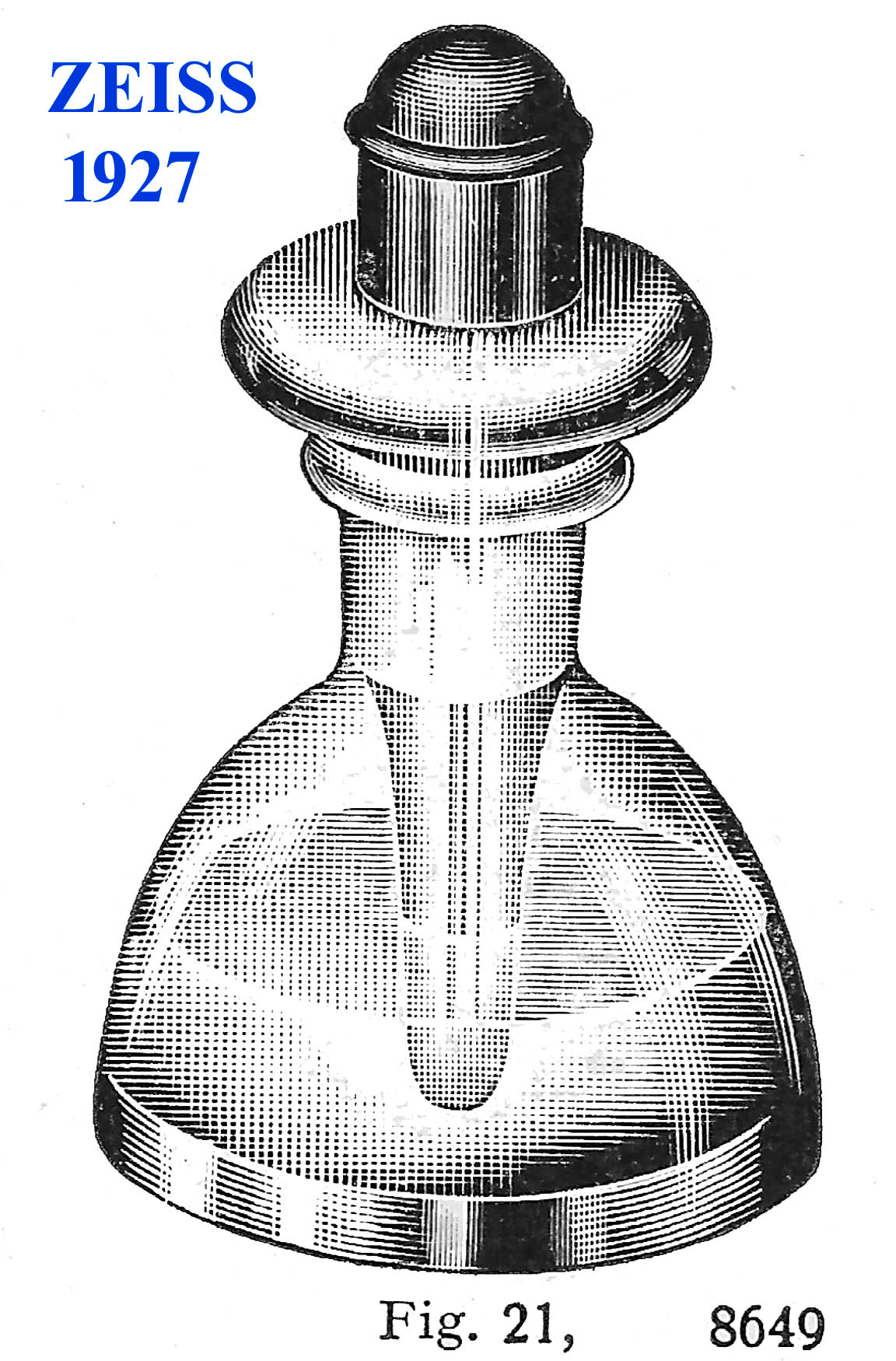

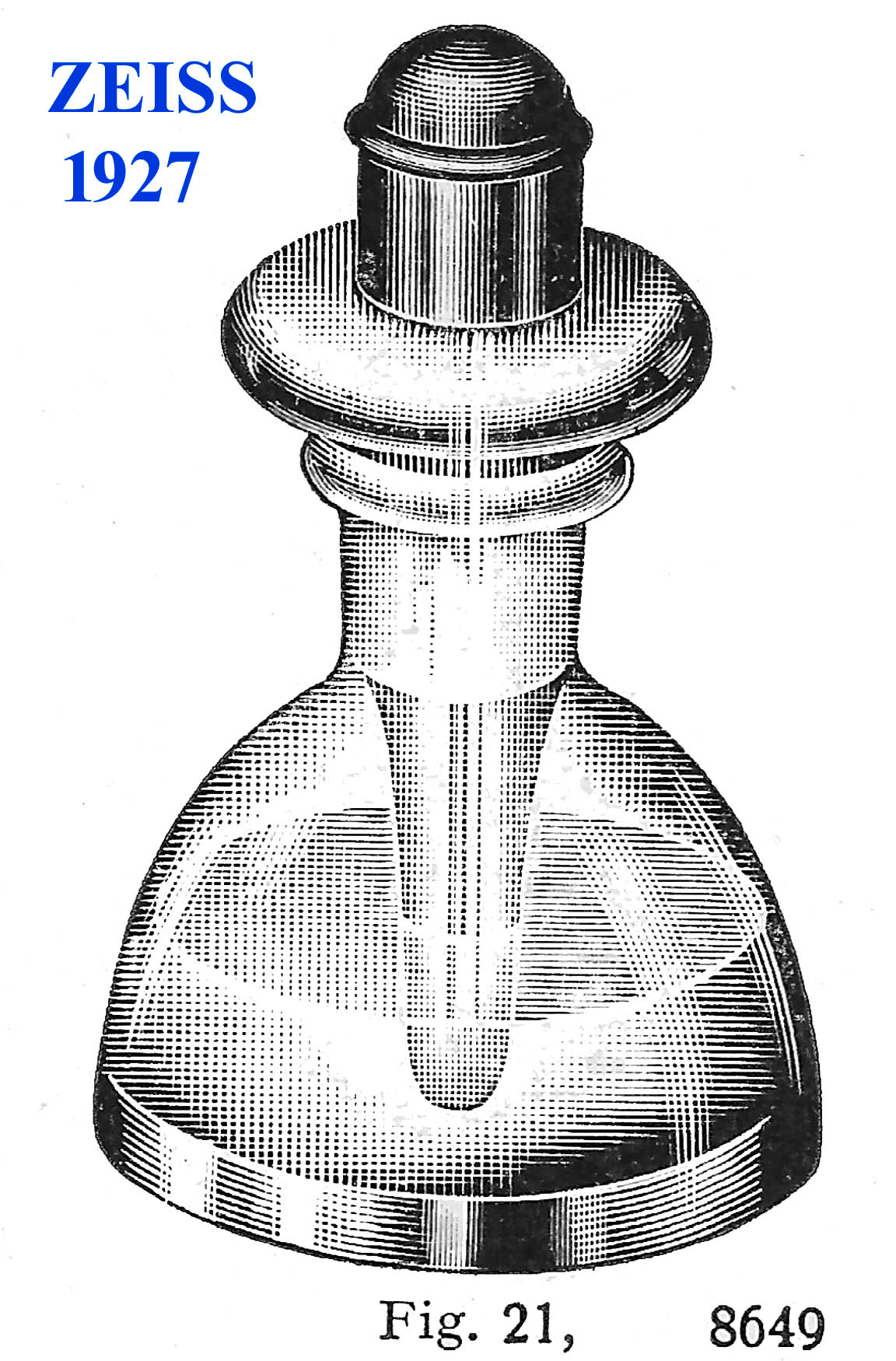

Sometime after 1913 and by 1927, the concentric double bottle described above reached its final form as shown in the 1927 Zeiss catalog(left). This final form, in Zeiss literature called the

Sometime after 1913 and by 1927, the concentric double bottle described above reached its final form as shown in the 1927 Zeiss catalog(left). This final form, in Zeiss literature called the Combined Immersion Oil Bottle and Bottle for the liquid for the Cleaning Objectives and Microscopic Preparations

, was apparently very popular and was also made in the U.S.A. by the T.C. Wheaton glass company(right). This type of bottle was so popular it was still being made by Wheaton in the 1960's, and an example is in this collection.

This bottle is really a bottle within a bottle. The outer clear bottle was designed to hold a solvent* and the small inner bottle was to be kept partially filled with immersion oil. The inner bottle serves as a ground glass stopper for the outer bottle, and the sealed tip of the inner bottle, immersed in the solvent, serves as a dropper for the solvent. The brass cap has a spring steel wire attached to it, over which is a glass rod sealed only on its lower end. By adjusting just how far the glass rod is allowed to protrude off the spring steel wire, the depth of it within the oil supply can be adjusted so that just the right amount of oil desired is removed when the cap with the wire and rod attached are removed.

A variation of the above bottle had a wire eyelet on the end of a piece of wire, doing away with the thin glass tube (image courtesy of James Solliday).

Although non-drying synthetic immersion oil became available in 1940, Cedar oil, the standard immersion oil since the 19th century remained readily available as immersion oil into the third quarter of the 20th century. (image modified from image courtesy of James Solliday).

First sold by Cargille in 1940, non-drying synthetic immersion oils became available and were sold or supplied by all the major makers. Although the conical type of bottle described above was still sold, many companies simply sold little bottles of immersion oil, either with screw caps, or screw caps with attached glass rods. Although these examples were sold by these companies in the mid-20th century, similar bottles are still supplied today by Cargille and other companies.

First sold by Cargille in 1940, non-drying synthetic immersion oils became available and were sold or supplied by all the major makers. Although the conical type of bottle described above was still sold, many companies simply sold little bottles of immersion oil, either with screw caps, or screw caps with attached glass rods. Although these examples were sold by these companies in the mid-20th century, similar bottles are still supplied today by Cargille and other companies.

When plastic became available little plastic dropper bottles were popular and these are still sold today. The plastic squeeze bottles have disadvantages in that although they can dispense oil in the desired amount, the tips of these bottles tend to attract dust to the oil remaining on the surface. In addition, the wider profile of the tip of these bottles makes it more difficult to apply the oil than with the glass bottles with thin glass rods built in to the caps, which are also still supplied today.

When plastic became available little plastic dropper bottles were popular and these are still sold today. The plastic squeeze bottles have disadvantages in that although they can dispense oil in the desired amount, the tips of these bottles tend to attract dust to the oil remaining on the surface. In addition, the wider profile of the tip of these bottles makes it more difficult to apply the oil than with the glass bottles with thin glass rods built in to the caps, which are also still supplied today.

Oils by Cargille and others contained PCBs until 1970 when Cargille was among the earliest companies to supply PCB-free oil. For this reason though, pre-1970 nondrying oils (1940-1971) should be treated as potentially toxic. WARNING: If these bottles(non-drying oil from before the 1970s) have oil in them, it would be wise not to open them. Cedarwood oil on the other hand, unless contaminated, is generally considered very safe and nontoxic.

* Xylol or benzene were used until benzene was banned as a possible carcinogen late in the 20th century and supplies of xylol were contaminated with benzene; in addition, heavy use of these would cause damage to the cement holding the optical elements of the objectives together. Toluene could also be used, but toluene may also be contaminated with benzene and its fumes are sometimes used as a substance of abuse and can cause severe toxicity. Nowadays the safest method used is simply wiping off the residual oil with a non-scratching cloth or paper, and then using a dilute soap solution to remove any residue instead of a solvent. But Xylol is still used by some people.

The first purpose made type of immersion oil bottle was simply a glass bottle with an applicator attached to the ground glass stopper. The applicator in this example by Bausch & Lomb is a camel-hair brush. Although the illustration shows a catalog entry from 1900, it was certainly available for years before that. The example shown here was designed to fit in a canister the same size as those for objectives, so it could store in the same fittings in the case as the objectives would. The lid served to hold the stopper firmly in place so oil would not leak out during traveling. Furthermore, the opening was wide enough to make it easier not to smear the oil on the sides of the opening when the stopper was withdrawn. This was important because cedar oil tends to dry out, gum up and might cause the stopper to become stuck.

The first purpose made type of immersion oil bottle was simply a glass bottle with an applicator attached to the ground glass stopper. The applicator in this example by Bausch & Lomb is a camel-hair brush. Although the illustration shows a catalog entry from 1900, it was certainly available for years before that. The example shown here was designed to fit in a canister the same size as those for objectives, so it could store in the same fittings in the case as the objectives would. The lid served to hold the stopper firmly in place so oil would not leak out during traveling. Furthermore, the opening was wide enough to make it easier not to smear the oil on the sides of the opening when the stopper was withdrawn. This was important because cedar oil tends to dry out, gum up and might cause the stopper to become stuck.

Bausch & Lomb eventually came up with a bottle made entirely of metal, again in the size, and of the style, of an objective canister. This nickel-plated example has a pointed bone, horn, or hard rubber applicator attached to to metal stopper. Again tightening the lid held the stopper tightly in place preventing leakage. The Leitz catalog of 1907 mentions an oil immersion applicator bottle with

Bausch & Lomb eventually came up with a bottle made entirely of metal, again in the size, and of the style, of an objective canister. This nickel-plated example has a pointed bone, horn, or hard rubber applicator attached to to metal stopper. Again tightening the lid held the stopper tightly in place preventing leakage. The Leitz catalog of 1907 mentions an oil immersion applicator bottle with

About 1897 Dr L Mach, of Zeiss in Germany, had devised a different kind of immersion oil receptacle, shown in cross section to the left. The overall conical shape was that of an Ehrlenmeyer flask. This was a single bottle with a inner glass cone through which a wire loop fit. There was a side port to fill the bottle and it was meant only to hold the oil such that a controlled amount could be removed and applied. The wide bottom prevented spillage. Note that the simpler cylinder-shaped type with glass rod applicator continued to be offered at the same time(right). For more details about this original form of Mach oil bottle, see here.

About 1897 Dr L Mach, of Zeiss in Germany, had devised a different kind of immersion oil receptacle, shown in cross section to the left. The overall conical shape was that of an Ehrlenmeyer flask. This was a single bottle with a inner glass cone through which a wire loop fit. There was a side port to fill the bottle and it was meant only to hold the oil such that a controlled amount could be removed and applied. The wide bottom prevented spillage. Note that the simpler cylinder-shaped type with glass rod applicator continued to be offered at the same time(right). For more details about this original form of Mach oil bottle, see here.

Sometime after 1913 and by 1927, the concentric double bottle described above reached its final form as shown in the 1927 Zeiss catalog(left). This final form, in Zeiss literature called the

Sometime after 1913 and by 1927, the concentric double bottle described above reached its final form as shown in the 1927 Zeiss catalog(left). This final form, in Zeiss literature called the

First sold by Cargille in 1940, non-drying synthetic immersion oils became available and were sold or supplied by all the major makers. Although the conical type of bottle described above was still sold, many companies simply sold little bottles of immersion oil, either with screw caps, or screw caps with attached glass rods. Although these examples were sold by these companies in the mid-20th century, similar bottles are still supplied today by Cargille and other companies.

First sold by Cargille in 1940, non-drying synthetic immersion oils became available and were sold or supplied by all the major makers. Although the conical type of bottle described above was still sold, many companies simply sold little bottles of immersion oil, either with screw caps, or screw caps with attached glass rods. Although these examples were sold by these companies in the mid-20th century, similar bottles are still supplied today by Cargille and other companies.

When plastic became available little plastic dropper bottles were popular and these are still sold today. The plastic squeeze bottles have disadvantages in that although they can dispense oil in the desired amount, the tips of these bottles tend to attract dust to the oil remaining on the surface. In addition, the wider profile of the tip of these bottles makes it more difficult to apply the oil than with the glass bottles with thin glass rods built in to the caps, which are also still supplied today.

When plastic became available little plastic dropper bottles were popular and these are still sold today. The plastic squeeze bottles have disadvantages in that although they can dispense oil in the desired amount, the tips of these bottles tend to attract dust to the oil remaining on the surface. In addition, the wider profile of the tip of these bottles makes it more difficult to apply the oil than with the glass bottles with thin glass rods built in to the caps, which are also still supplied today.