HARDNESS TESTER FOR USE WITH MICROSCOPE

MAKER: SPENCER

c. 1945

DATES of PRODUCTION: 1920's to 1950's(?)

SIGNED:'MICROCHARACTER, American Optical Co, Buffalo 15, N.Y., Made in U.S.A.'

Please Click On Any Picture for a Larger Version

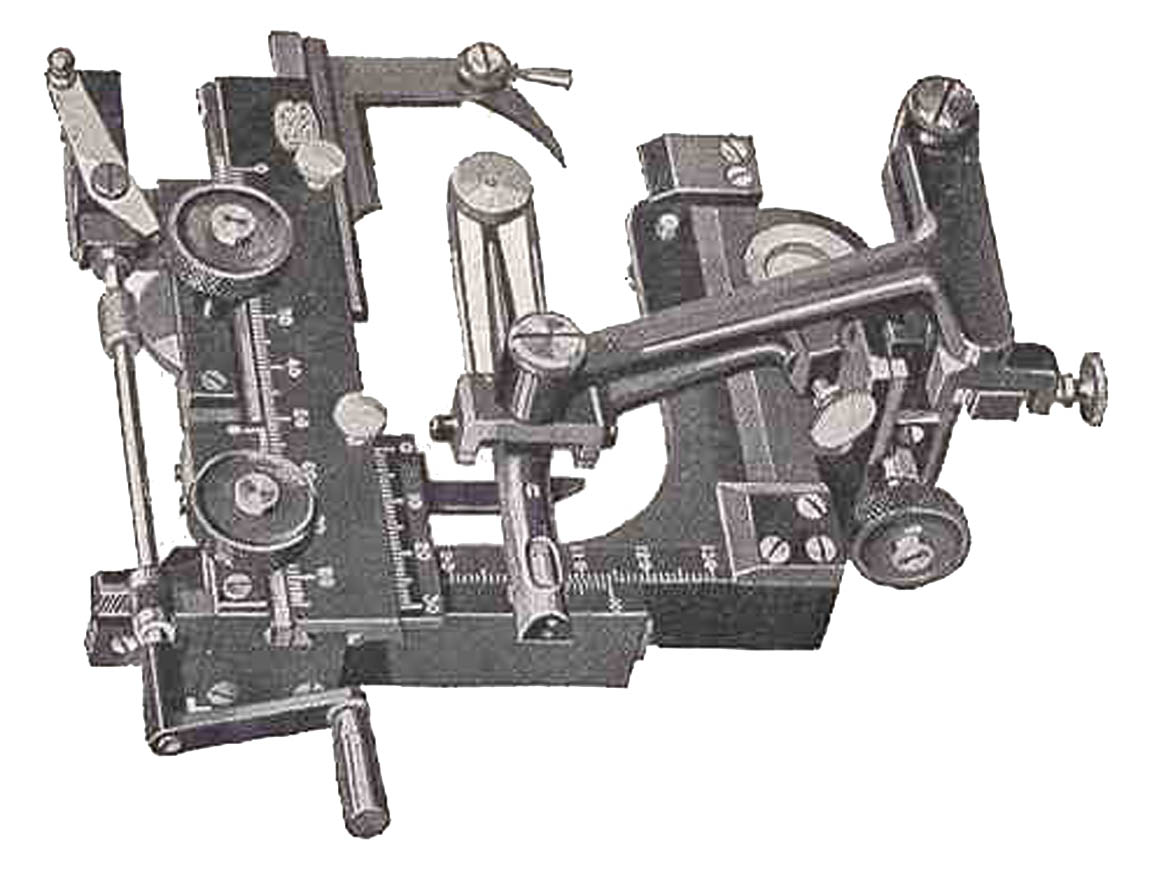

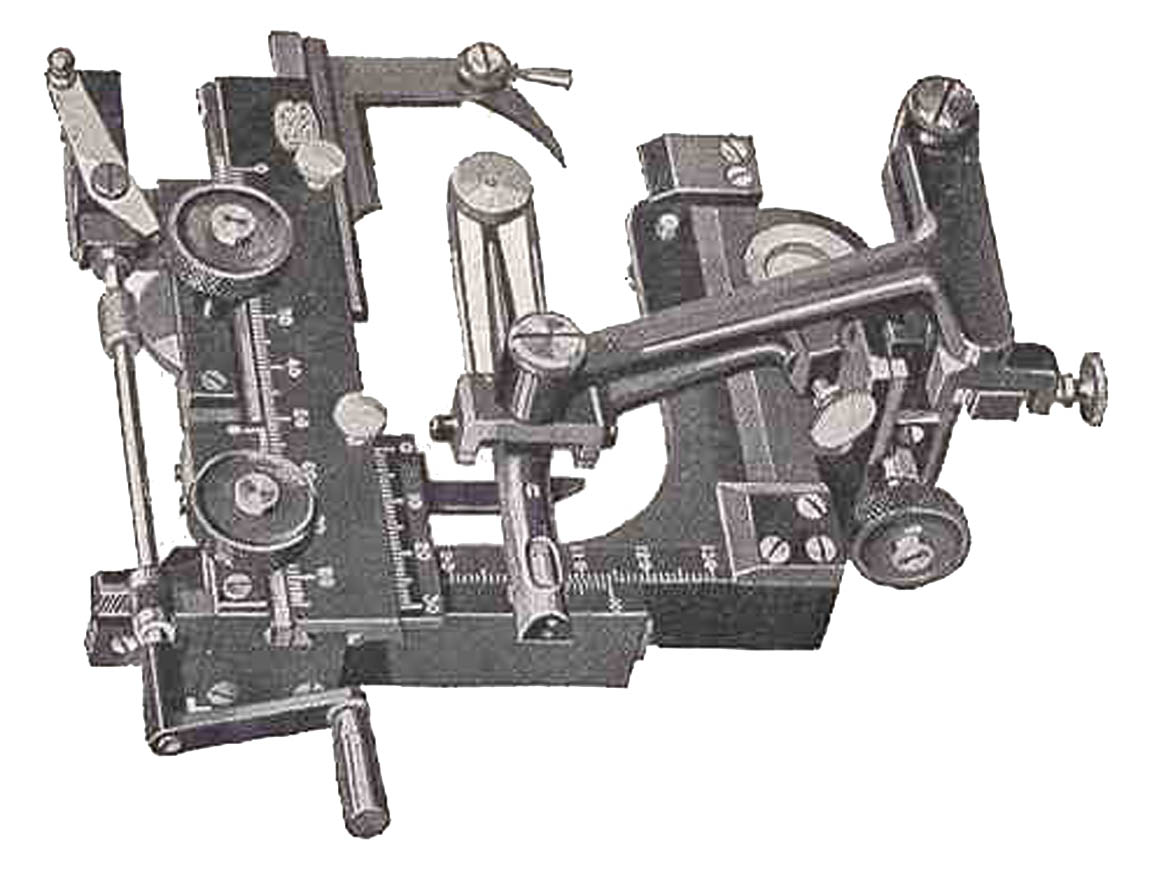

DESCRIPTION: This device is signed: 'MICROCHARACTER, American Optical Co, Buffalo 15, N.Y., Made in U.S.A.' It is a device for testing the 'hardness' of metals and crystals on a microscopic scale. The device is designed to attach to a standard square or rectangular microscope stage using three knurl-knobed screws. It resembles a mechanical stage but has a two spirit levels,and provides an arm, to the end of which is attached a gemstone (early on saphire, later, as on this example, a diamond), cut in a cube with a corner of the cube serving as a cutting surface. It has calibrated slide holders which can be adjusted to different distances from each other to suit slide size, and may be kept at the separation distance by knurled knobs. Once the object to be studied is centered (using the mechanical stage controls), and the cutter is adjusted to make the movement of the stage parallel to the cutting edge, the user engages and then turns the crank which slowly moves the slide under the weighted cutter, resulting in a 'scratch'. Cedar oil is used as a lubricant prior to making the scratch. This oil must be removed from the cutter after each use utilizing a solvent such as xylene. The width of the scratch is then measured with an ocular micrometer and is proportional to the hardness of the material. A figure identifying the individual controls for these operations can be seen on this site. Under the microscope it is easy to tell if there are variations in hardness on a microscopic scale, as the width of the cut will change when the hardness changes. The formula used for a 3 gram load is:

Bierbaum Microhardness= 104/w2,

which is the ratio of the load in Kg to the width in mm.

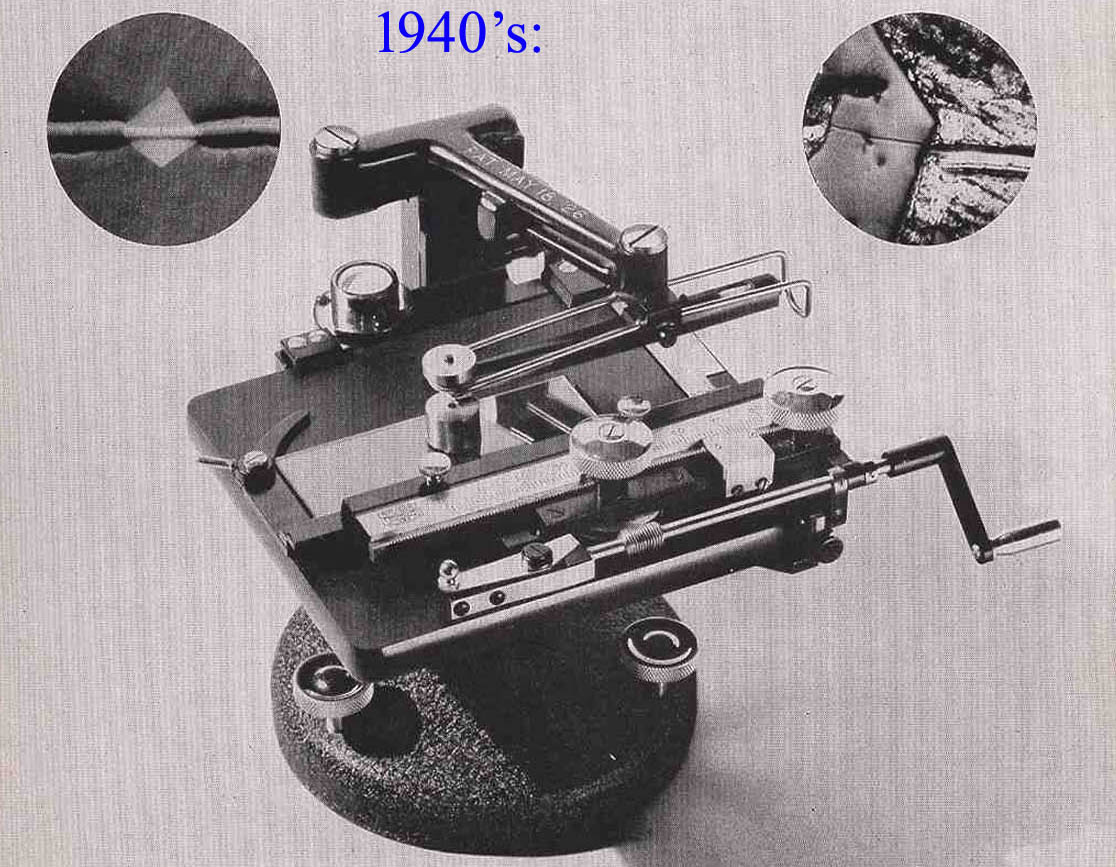

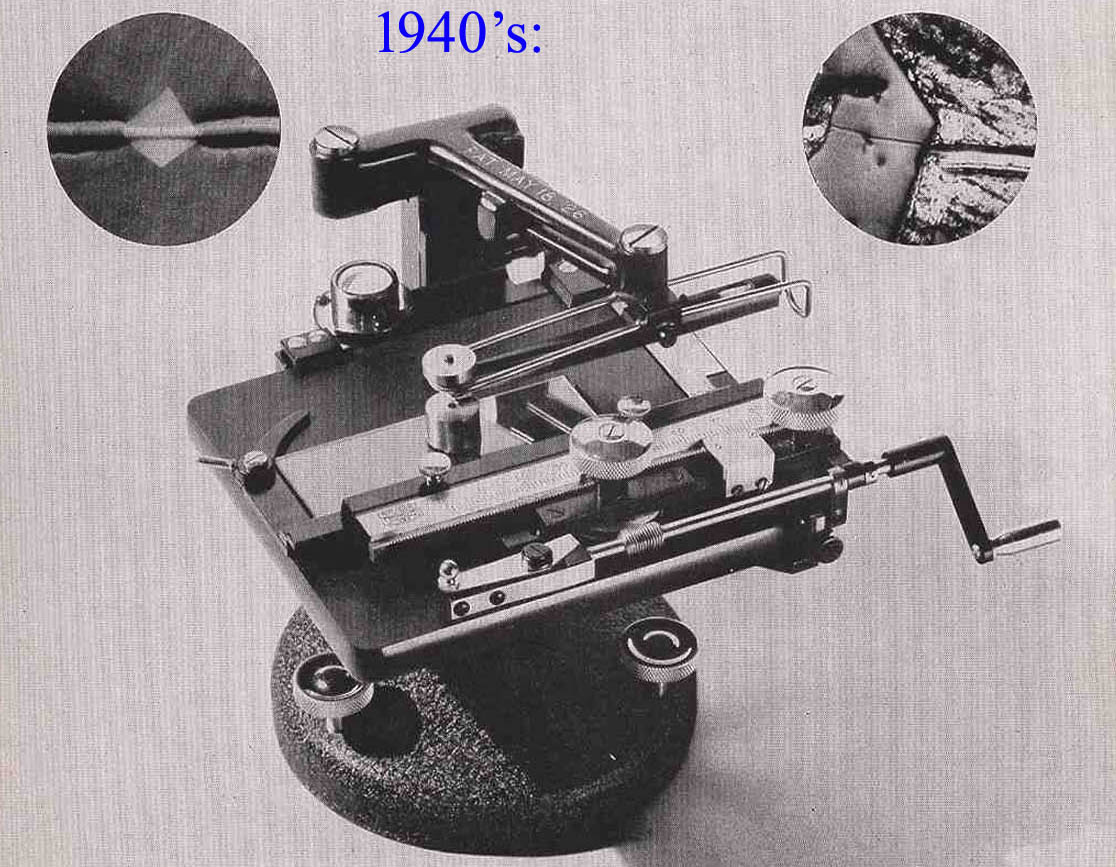

Use of this device requires not only an eyepiece micrometer, but also a vertical illuminator. Early on, a Ramsden screw micrometer and an electric vertical illuminator were supplied with the microcharacter. Later on, these became additional options, so that if one already possessed one or both of these accessories, they did not need to purchase them again. This example includes both a 3 gram weight and a 9 gram weight; there was a controversy about which weight was the optimal one to use. It also has a receptacle in the case for an eyepiece micrometer and additional space for a vertical illuminator or other accessories. The latest catalog entry for the Microcharacter I have, shows it setup on a leveling stand of its own; presumably the slide would then be examined on a separate microscope.

The microcharacter was an expensive device costing about $4000 in 2019 dollars. It is a rarely seen accessory. A detailed description of the device is included in the original patent of May 1926. For simplicity, in addition to the illustrations referred to above, I have also provided an abridged key to the patent drawing numbers, which eliminates the text of the patent and simply identifies each numbered component.

HISTORY OF THE MICROCHARACTER:

The 'Microcharacter' was invented by Christopher Bierbaum. He submitted his request for patent on Dec 29, 1920 and he was granted U.S. Patent No. 1,585,278 on May 18, 1926. It is one of several methods of testing hardness of metals and other materials, but at the time was one of the only ones that could do so on a microscopic scale. Apparently the 'Microcharacter' was offered in the catalogs by Spencer starting in 1924 and called the 'Spencer Microcharacter' and sold as an attachment to the stage, as shown in the catalog entry. That early entry notes that the microcharacter was sold as a package with a Ramsden Eyepiece Micrometer and an electric illuminator.

The 'Microcharacter' was invented by Christopher Bierbaum. He submitted his request for patent on Dec 29, 1920 and he was granted U.S. Patent No. 1,585,278 on May 18, 1926. It is one of several methods of testing hardness of metals and other materials, but at the time was one of the only ones that could do so on a microscopic scale. Apparently the 'Microcharacter' was offered in the catalogs by Spencer starting in 1924 and called the 'Spencer Microcharacter' and sold as an attachment to the stage, as shown in the catalog entry. That early entry notes that the microcharacter was sold as a package with a Ramsden Eyepiece Micrometer and an electric illuminator.

Sometime in the 1940's it was offered as a stand-alone device, now called the 'Spencer-Bierbaum Microcharacter'. It came on a leveling table, the slide being tested simply needed to be removed after etching it with the device and placed on a separate microscope with vertical illuminator and ocular micrometer for measurement. The vertical illuminator and micrometer eyepiece were no longer included and were now sold separately.

It has been said that Zeiss also made a similar devices, though I have no details as yet.

Sometime in the 1940's it was offered as a stand-alone device, now called the 'Spencer-Bierbaum Microcharacter'. It came on a leveling table, the slide being tested simply needed to be removed after etching it with the device and placed on a separate microscope with vertical illuminator and ocular micrometer for measurement. The vertical illuminator and micrometer eyepiece were no longer included and were now sold separately.

It has been said that Zeiss also made a similar devices, though I have no details as yet.

The 'Microcharacter' was invented by Christopher Bierbaum. He submitted his request for patent on Dec 29, 1920 and he was granted U.S. Patent No. 1,585,278 on May 18, 1926. It is one of several methods of testing hardness of metals and other materials, but at the time was one of the only ones that could do so on a microscopic scale. Apparently the 'Microcharacter' was offered in the catalogs by Spencer starting in 1924 and called the 'Spencer Microcharacter' and sold as an attachment to the stage, as shown in the catalog entry. That early entry notes that the microcharacter was sold as a package with a Ramsden Eyepiece Micrometer and an electric illuminator.

The 'Microcharacter' was invented by Christopher Bierbaum. He submitted his request for patent on Dec 29, 1920 and he was granted U.S. Patent No. 1,585,278 on May 18, 1926. It is one of several methods of testing hardness of metals and other materials, but at the time was one of the only ones that could do so on a microscopic scale. Apparently the 'Microcharacter' was offered in the catalogs by Spencer starting in 1924 and called the 'Spencer Microcharacter' and sold as an attachment to the stage, as shown in the catalog entry. That early entry notes that the microcharacter was sold as a package with a Ramsden Eyepiece Micrometer and an electric illuminator. Sometime in the 1940's it was offered as a stand-alone device, now called the 'Spencer-Bierbaum Microcharacter'. It came on a leveling table, the slide being tested simply needed to be removed after etching it with the device and placed on a separate microscope with vertical illuminator and ocular micrometer for measurement. The vertical illuminator and micrometer eyepiece were no longer included and were now sold separately.

It has been said that Zeiss also made a similar devices, though I have no details as yet.

Sometime in the 1940's it was offered as a stand-alone device, now called the 'Spencer-Bierbaum Microcharacter'. It came on a leveling table, the slide being tested simply needed to be removed after etching it with the device and placed on a separate microscope with vertical illuminator and ocular micrometer for measurement. The vertical illuminator and micrometer eyepiece were no longer included and were now sold separately.

It has been said that Zeiss also made a similar devices, though I have no details as yet.